CASE STUDY

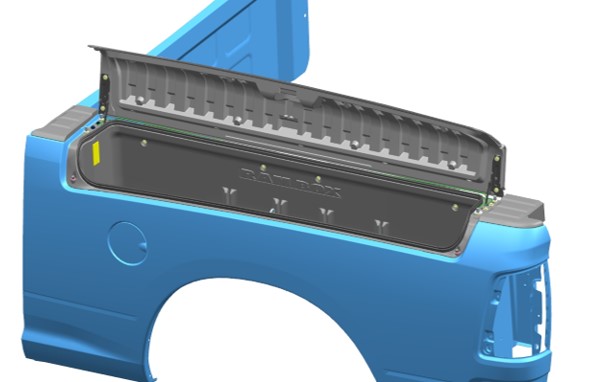

RamBox

Challenge

Design, build and validate inner fender storage box system for Dodge trucks. Working within a restricted timeline of 18 months from concept to production. Develop custom materials to meet thermal, strength, and impact requirements.

DESIGN & ENGINEERING

FEA to analyze lid deflection with seal, plunger switch and torque rod forces along with cooling impacts.

PROTOTYPING

Built a prototype lid tool with deflection, and cooling compensation. Evaluated the required texture at different depths to match the surrounding injection molded parts.

PRE-TOOL TESTING

Built a CNC aluminum buck to analyze lids in the installed position to nominal sheet metal.

SOURCING AND ASSEMBLY

Met tight dimensional requirements of perimeter tolerance +/- 1.5mm on a 65.5" lid.

Overview

Working with our OEM engineering group, Penda provided unique solutions to marry style and functionality of the Ram Box.

We have also custom developed materials to meet thermal, strength, and impact requirements.

FINISHED COMPONENTS

- Thermoformed lid

- Injection molded bin

- Injection molded color match applique panel

- Electrical system with harness, lights and switches & remote operated lock

- Hinge and torsion rod system

- Seals & drain plug

- Lock and latch system

Solution

Penda provided improved tool timing and low cost in order to assure on-time delivery. Engineered and developed a heavy- impact structural solution required for bin and lid.

Automated in line check fixtures were implemented to assure every assembly met the specifications.

Results

Working with Penda allowed for production of +/- 1.5mm flush & gap dimensional product tested for water intrusion & car wash, closing effort, durability, environmental, corrosion, lid cycle, impact, vibration, thermal extremes, anti-theft, BSR, static load, freeze test.